Feature:

● Siemens system

● New Technology for Feeding

● Euro Market Quality

Introduction:

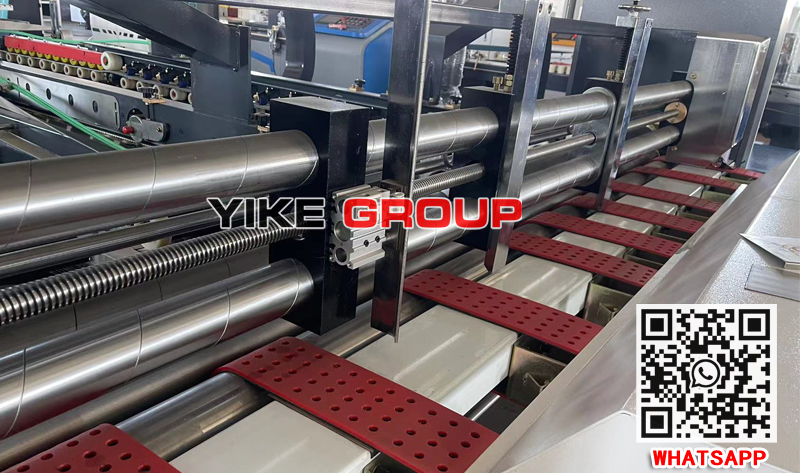

Computer type automatic glue machine is consist of three parts, which is paper feeding part, gluing and folding part and counting and stacking part. Automatic Computer adjustment paper feeding / fold and glue. Automatic counting and stacking output. Wall board thickness 40mm. The speed can reach 150-200 pieces per minute. Advanced and reasonable structure design and manufacture, it demands for cultural level of operators is not high, and operators will be able to handle all operating procedures in one or two working days, and protect the safety of operating personnel. Delta touch scree, PLC, Inverter, China Famous Brand bearings.

Feeding unit

l The vacuum suction feeding system, accurate and reliable.

l The use of high-end electromagnetic clutch and electromagnetic brake system, so that the paper can be controlled separately, the operation is simple and reliable.

l Pressure roller adjustable, suitable for cardboard thickness 2-8mm.

l linkage and folding department, frequency control, feeding speed 120m / min.

l The front baffle and feed belt of the paper feed section are adjustable left and right.

Folding and gluing unit

l The main motor adopts frequency control, the system has no noise, speed regulation is flexible and stable.

l imported high friction belt conveyor cardboard, automatic folding.

l With stainless steel wheel coating, glue evenly, trouble-free, but also save plastic.

l Folding Department equipped with cardboard correction device and indentation correction device.

COUNTER AND STACKER UNIT

l Using digital control, simple operation, reliable operation, non-stop input data, automatic counting, accurate output.

l The use of belt conveyor cartons, neatly stacked.

l separate drive, differential, with correction function, the deviation can be adjusted.

l Counting and the introduction of pneumatic way, reliable action, accurate and fast.

Specification:

| Model | YK-1226 |

| Max. Cardboard | 1200*2600mm |

| Mini. Cardboard | 170*440mm |

| Diemensions | 15500×3000×1600mm |

| Power required | 12 kw |

| Speed | 150-200 Pcs/min |

| Voltage | 220V/380V/415V |

AUTOMATIC PP Belt strapping machine

1. The machine is mainly composed of 4 units: receiving sheet turning unit, pat in order unit, conveying unit, and pressurized strapping unit.

2. Reduce rely on manpower, replace workers.

3. Work is compact, no need human intervention

4. Carton boxes after strapping are mouth tight and solid, no rebound, less sticky box edge breakage, etc

5. Less workers, higher speed, 2 ~ 4workers less than ordinary strapping machine, 10 to 20 workers less than manual strapping.

6. Suitable for exported packaging, environmental packaging, such as drinks box, beer case, instant noodles box, ceramic tile box, these high class packaging carton boxes.

7. Max sheet size: 1100x1100mm

8. Min sheet size: 300x350mm

Ø The functional characteristics:

1. This product is suitable for use in carton manufacturers for matching glue boxes or ordering lines. The finishing package can be adjusted automatically according to the carton size.

2. The form of strapping: parallel 1-2 channels, the way there are photoelectric, manual and so on.

3. The ram steering power roller conveyor line: speed: 45mm / min.

4. The bottom bonding surface ≥ 90% bonding width ≥ 20mm bonding position deviation ≤ 0.5mm

5. As needed: configure the EFFL telescopic rack connected to other equipment.

6. The size of the transport equipment: length 4850 × width 2300 × height 2000 (excluding telescopic rack)

Ø The equipment technical parameters:

1. Power supply 380V/50HZ 2KW/5A

2. Speed ≤ 12-14 packets / min. (depending on the size of the carton)

3. Gas source: 6kg/cm3.

4. Table height: 850mm.

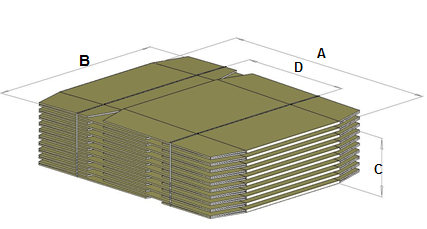

5. Package size: A: L (300-1150) B: W (350-1150) C: H (0-350) mm

6. Applicable packing belt: Width 5mm, Thickness 0.6mm.

7. Strapping form: Parallel 1-2 channels, the way there are photoelectric, manual and so on.

8. Noise: Under working environment, the noise is ≤75DB.

Ø Steering section:

1. The drum is made of stainless steel tube wall 1.5mm.

2. The roller bearing adopts the Harbin brand.

3. The position of the ram is manually adjusted by the screw according to the size of the carton.

4. The fastest speed of the steering line: 50m/min.

Ø Push In Line:

1. The drum is made of stainless steel tube wall 1.5mm.

2. The roller bearing adopts the Harbin brand.

3. The motor adopts frequency conversion control, starts up, runs smoothly, and can adjust the speed of the slap according to the size of the carton.

4. Adjust the size of the carton to be completed by manually adjusting the screw.

5. The fastest speed : 70m / min

Ø The packaging department:

1. With one unmanned pressure baler, the frame size is 1250 wide × 500 high

The machine size is 1520×680×2000mm.

2. Applicable packing belt: width 5mm, thickness 0.6mm.

3. Bearing capacity: 80Kg.

4. Reel: The inner diameter of the roll paper core is 200mm-210mm, the outer diameter of the roll is 400mm-450mm, and the width of the roll is 170mm-190mm.

5. Bonding method: hot melt method.

6. Strapping tightness: 0-45Kg.

7. Strapping form: parallel 1-2 channels, the way there are photoelectric, manual and so on.

8. The bottom bonding surface is ≥90%, the bonding width is ≥20mm, and the bonding position deviation is ≤0.5mm.

9. Electrical configuration: Panasonic PLC; Schneider inverter; Schneider contactor; Taiwan Yadeke cylinder; Taiwan Wanxin motor.

Ø Laifu wheel telescopic conveyor:

1. The reed telescopic carriage of Laifu Wheel has the characteristics of flexible expansion, flexible use and labor saving. Sizes can be customized as needed.

2, easy to use and installation, a unit can be up to three times the shortest and longest.

Ø Packing pipeline configuration sheet

Motor | Taiwan Wanxin, Shanghai Yinda, Mengniu |

The electrical appliances | |

PLC | Panasonic |

Contactor | Schneider |

Button | Schneider |

Inverter | Schneider |

Intermediate relay | Omron |

Switching power supply | Mingwei |

Text display | Xinjie |

Transformer | Zhengtai |

Thermal relay | Zhengtai |

Circuit breaker | Zhengtai |

Terminal block | Chint |

Photoelectric switch | Hugong |

Conveyor belt | Shenzhen Belt Lida |

Roller | Huzhou Jiutong Technology |

Cylinder | Proximity switch Yadeke |