Feature:

● Delta system

● New Technology for Feeding

Introduction:

Computer type automatic glue machine is consist of three parts, which is paper feeding part, gluing and folding part and counting and stacking part. Automatic Computer adjustment paper feeding / fold and glue. Automatic counting and stacking output. Wall board thickness 40mm. The speed can reach 150-200 pieces per minute. Advanced and reasonable structure design and manufacture, it demands for cultural level of operators is not high, and operators will be able to handle all operating procedures in one or two working days, and protect the safety of operating personnel. Delta touch scree, PLC, Inverter, China Famous Brand bearings.

Specification:

Type | YK-2600 |

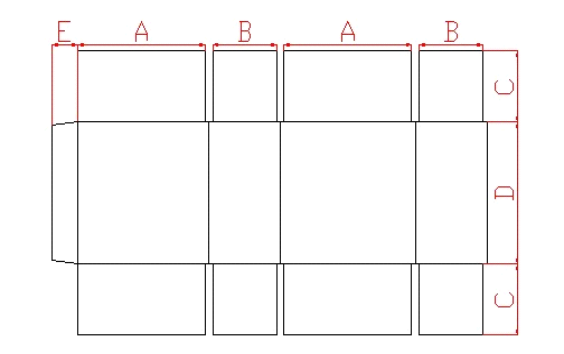

尺寸A+B(mm) | 210-1300 |

尺寸C+D+C(mm) | 170-1300 |

设备尺寸(mm) | 3500×11000 |

安装面积(mm) | 4200×15000 |

电机功率(kw) | 12kw |

一、Paper supply department

1. The paper is fed by belt front edge suction, which is accurate and reliable.

2. Adopt high-grade electromagnetic clutch and electromagnetic brake system, so that the paper feeding part can be controlled independently, and the operation is simple and reliable.

3. The pressing roller is linked with the folding part, the height is adjustable, and the thickness of the cardboard is 2-8mm.

4. The paper feeding wheel is linked with the folding part, the speed is controlled by frequency conversion, and the paper feeding speed is 0-230m/min.

5. The front baffle and the paper feeding belt of the paper feeding section are adjustable from left to right, and equipped with an air cylinder clapping device, which claps the cardboard at regular intervals to ensure that the paper is fed neatly.

二 、Gluing and folding part

1. The main motor adopts frequency conversion speed regulation system without noise, flexible and stable speed regulation.

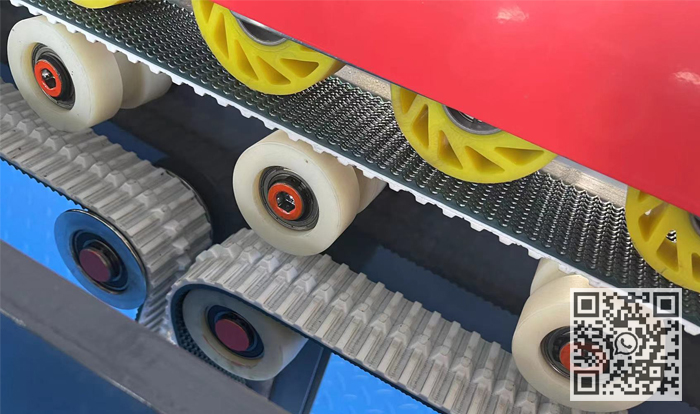

2. Imported high-friction synchronous belts are used to transport cardboard, automatic stacking, strong suction, preventing belt slippage, accurate and reliable paper feeding, and no deviation.

3. Stainless steel wheel is used to apply glue, the amount of glue is even, trouble-free and glue-saving.

4. The folding part is equipped with a cardboard correction device and an indentation correction device.

5. There are two rows of adjustable inner positioning guide wheel system in the folding part, which has higher forming precision.

6. Folding speed 0-230m/min.

三、Counting and stacking department

1. Automatic stacking and neat output.

2. The main motor of the technical department has frequency conversion speed regulation, the speed is adjustable, and the starting is stable and reliable.

3. The cartons are conveyed by the belt, stacked neatly, and the speed is 0-230m/min.

4. Use the beating board to hit the carton, which has the function of correcting the deviation, and the deviation is very small.

5. Pneumatic method is used for counting and ejection, PLC electric control, reliable action, accurate and fast.

6. It adopts PLC programming controller and touch screen digital control, which is easy to operate, reliable in action, input data without stopping, and automatically count.

7. The output part adopts the synchronous pressing method of the bottom conveyor belt and the upper pressing belt, so that the finished cartons are firmly glued and output neatly.

8. Differential gear adjustment is used to forcibly and effectively correct fishtail scissors and other phenomena.